Services

Services

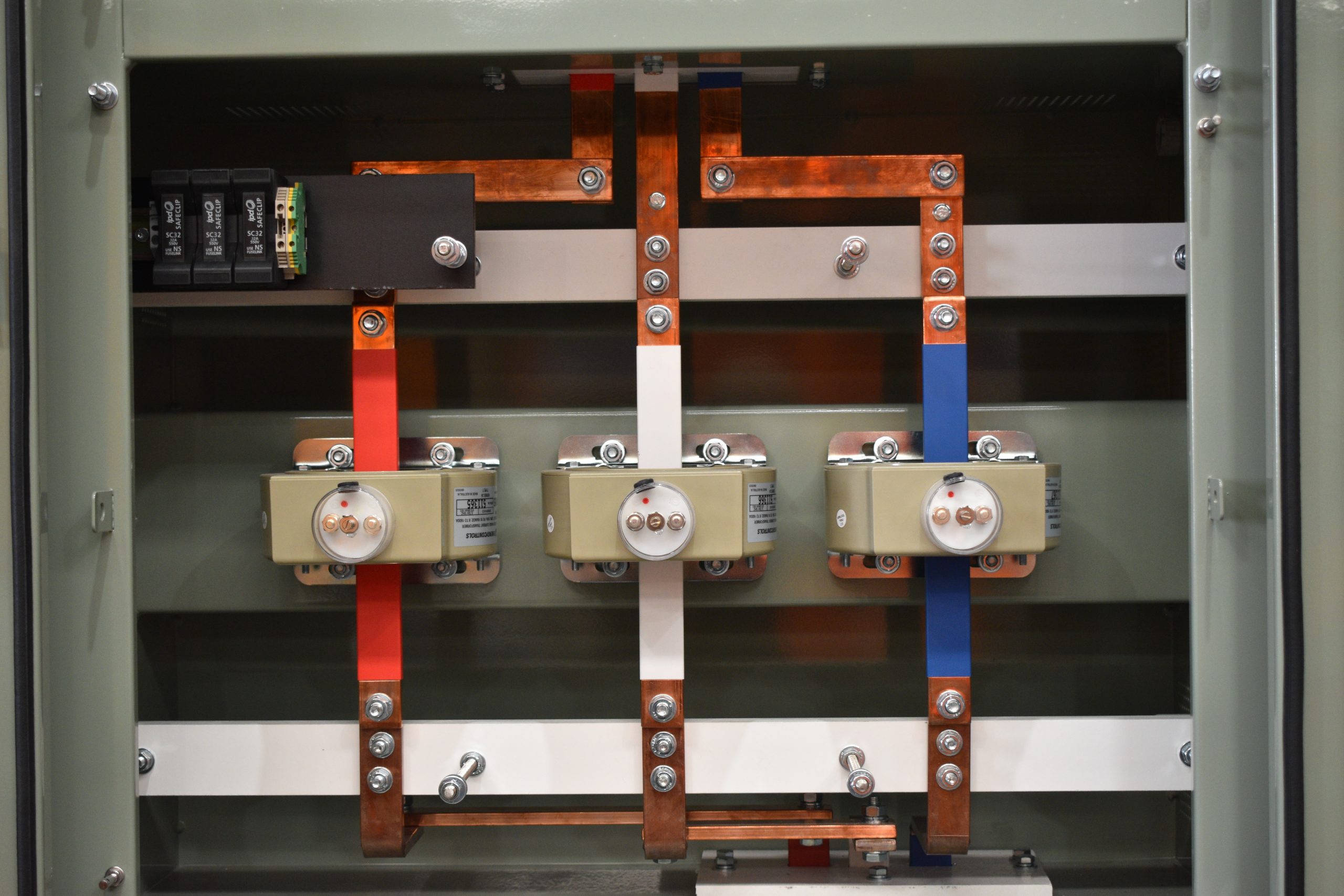

Crafting bespoke low-voltage switchboards is our passion—precision-driven solutions designed exclusively for your needs, ensuring seamless electrical efficiency.

Switchboard Maintenance & Replacement

Protect one of your largest investments with a regular and thorough maintenance program. Power outages can result in potentially costly down-times. Have your switchboard checked regularly by experienced Chadwick Switchboard specialists.

Faults in switchboards don’t always come from old and/or faulty switchgear. They can occur from dust build up, water leaking, vermin infestation and cable joints that loosen from heating and cooling over time. Simple tasks by our qualified specialists such as regular cleaning or tightening cable connections will help ensure your business remains operational.

After our team has carried out maintenance, we’ll provide a report outlining works carried out as well as recommendations that can help avert future electrical interruptions or even catastrophic switchboard failures resulting in costly replacements and down-times.

On-Site Switchboard Modifications

Backed by an experienced team of engineers and switchboard designers, Chadwick Service Technicians attend to many shutdowns each year. They have earned a reputation of being industry leaders by providing a reliable service, completing works on time and to a high standard.

Typical modifications range from installing new switchgear to replacing whole sections to adding complete tiers to existing switchboards. Modifications typically also require switchboards to be brought up to current standards.

Contact our engineering staff today to find out if your existing switchboard meets current statutory regulations and can be modified to meet future needs.

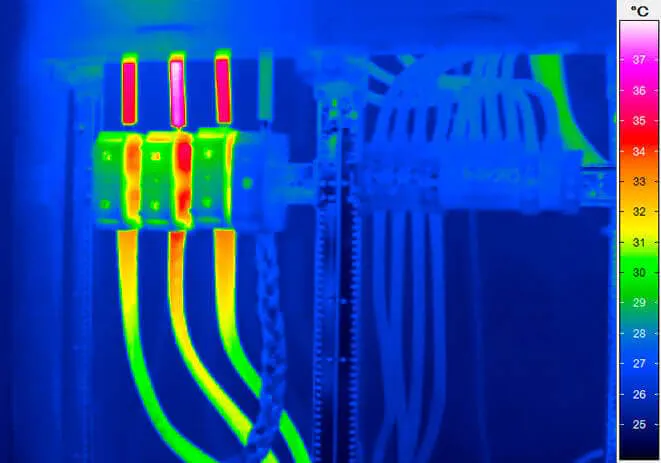

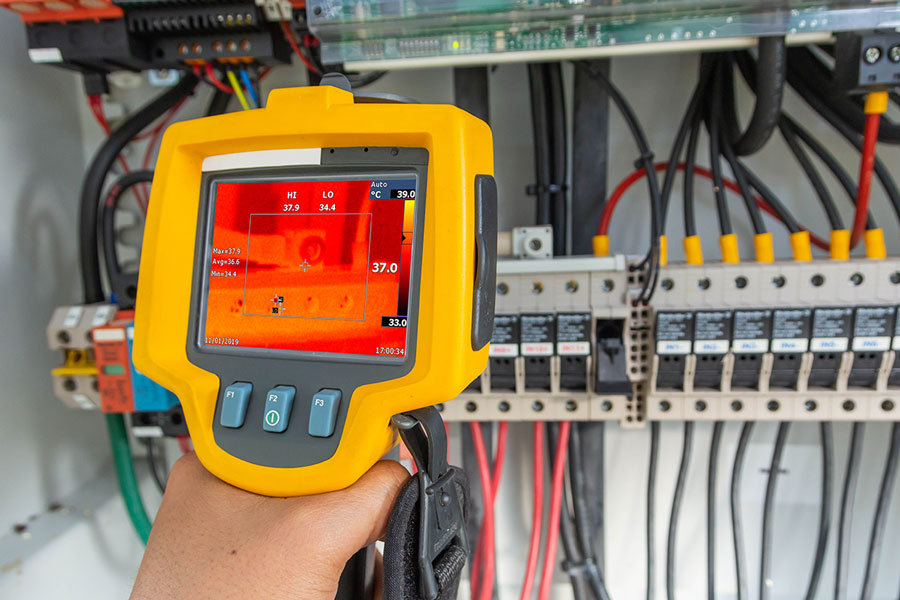

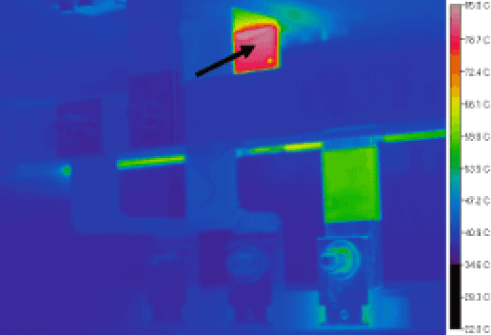

Thermographic Switchgear Grading Studies

One of the main causes of switchboard fires is undetected hot spots. Hot joints often occur at high resistance joints such as loose cable connections or overloaded switchgear. If left overlooked, they can cause costly downtimes or even incidents like fires. Using thermal imaging technologies, potential problems that are otherwise undetectable to the naked eye, can be rectified before they become major switchboard faults.

Thermal imaging surveys can be carried out during normal business hours with no disturbance to your business. They represent an effective pre-emptive strategy to manage your switchboard assets. Any repairs can be made around your business operations rather than lengthy interruptions after the equipment fails.

For peace of mind make thermal imaging part of your regular maintenance program. Better yet, ask us to carry out your next switchboard maintenance undertaking. Be sure to mention you want the thermal imaging option.

In-House Switchboard Design/Engineering

Whether your switchboard was purchased from Chadwicks or not. We still can provide spare parts when existing components become redundant or faulty.

With Chadwick Sales, you are not just purchasing switchboard components. You have access to years of experience that can assist you in ensuring that what you are buying will do the job. We can advise you on alternatives, if any are available, that are technically more suited or even a more cost effective solution.

For instance, in purchasing a new circuit breaker, we consider fault levels, grading, and whether or not it’s fit for purpose – eg. a normal circuit breaker is not suitable for welders.

Chadwick Sales is available by phone, email or office.

Spare Parts

Whether your switchboard was purchased from Chadwicks or not. We still can provide spare parts when existing components become redundant or faulty.

With Chadwick Sales, you are not just purchasing switchboard components. You have access to years of experience that can assist you in ensuring that what you are buying will do the job. We can advise you on alternatives, if any are available, that are technically more suited or even a more cost effective solution.

For instance, in purchasing a new circuit breaker, we consider fault levels, grading, and whether or not it’s fit for purpose – eg. a normal circuit breaker is not suitable for welders.

Chadwick Sales is available by phone, email or office.

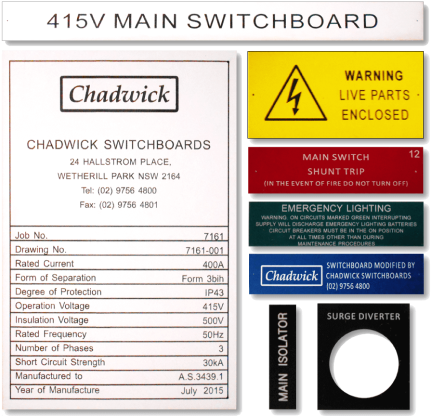

Labelling

Do you need labels to finish off your project?

Not only do we make electrical switchboards, we also manufacture custom labels, tags, & signs using our CO2 laser engraver.

Our labels are laser engraved using impact modified acrylic available in a variety of colours and finishes. For the full range of colours and styles, see our labels data sheet here.On special request, we can engrave stainless steel, aluminium, brass, acrylic, glass & even timber.

Ranging from identification labels to company logos to complex CAD Drawings. Our labelling facilities can help you add the finishing touches to your projects.